9 December 2025

A Q&A with Inther Group CEOs Martijn Herder and Paul Hermsen about China — a country where new e-commerce models emerge almost monthly, and automation cycles move at unprecedented speed.

A Global Integrator with Local Speed

Since 1998, Inther Group has been known as a full-service system integrator, designing and implementing intelligent material handling solutions worldwide. With headquarters in the Netherlands and projects spanning Europe, North America, Asia and Australia, the company’s software-driven approach has made it a trusted partner in warehouse automation. Yet few markets are transforming logistics as rapidly as China — a country where new e-commerce models emerge almost monthly, and automation cycles move at unprecedented speed. In this interview, CEOs Martijn Herder and Paul Hermsen explain why China is more than just another market — it’s the heartbeat of logistics innovation.

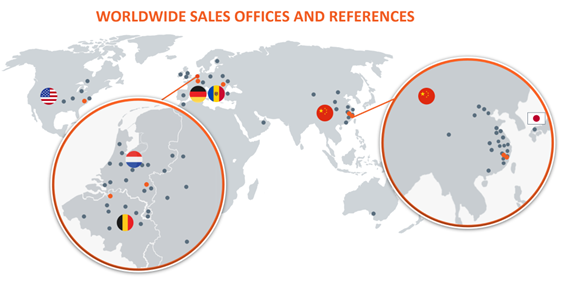

Figure 1. Inther Group worldwide sales offices and references.

Figure 1. Inther Group worldwide sales offices and references.

Riding the Wave of Constant Change

Reporter: Let’s start with the big picture — why did Inther choose to establish and maintain a strong presence in China?

Martijn Herder: Because China is where the logistics world moves fastest. The pace of innovation, automation, and change here is unlike anywhere else. Every month, new warehouse models, robotics solutions, and customer demands emerge. For a company like Inther — rooted in integration and adaptability — China is both a challenge and an inspiration. It keeps us sharp. We learn here every day, and what we learn flows back into our global projects. It pushes us to innovate continuously. What we learn in China strengthens our global capabilities.

Reporter: So it’s more about learning and innovation than just market expansion?

Paul Hermsen: Exactly. China isn’t only a market — it’s a laboratory for logistics evolution. When parcel volumes reach hundreds of billions annually, the entire ecosystem innovates at hyperspeed. By being here, we don’t just sell systems; we stay ahead of what’s coming next globally.

From Presence to Partnership

Reporter: How has that philosophy shaped your footprint — now with two locations in China?

Herder: We began modestly, but to truly serve the market we needed proximity. Shanghai handles our commercial and customer-facing activities, while Suzhou focuses on engineering and production. Together, they make us faster and more responsive. It’s about being inside the ecosystem, not just observing it. It’s about speed, flexibility, and being part of the daily logistics dialogue.

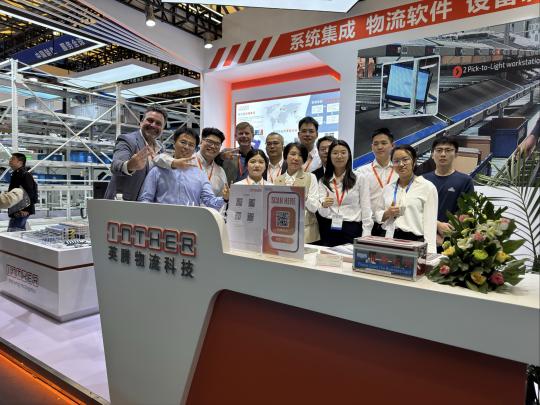

Figure 2. Inther Group sales team at CeMAT China 2025

Reporter: Inther has been in China for quite some time. What lessons stand out?

Herder: Local presence is non-negotiable. In our early Chinese projects, we learned that being able to speak the language, share time zones, and solve issues on-site makes all the difference. It’s why we’ve invested continuously — from service engineers to production lines — rather than managing remotely from Europe.

Building Locally, Thinking Globally

Reporter: What drove the decision to start a joint venture for hardware manufacturing?

Hermsen: Control and agility. We wanted to shorten lead times and customize for local standards without compromising quality. Partnering with Yugasum allowed us to co-develop a line of modular conveyor and sortation equipment built to Inther’s software and safety standards but optimized for local production and component availability.

Reporter: Was that primarily a cost decision?

Hermsen: Not really. Costs matter, but the key driver was speed and market fit. When you can design, test, and produce within the same region, iteration cycles shrink dramatically. For customers, that means faster delivery; for us, it means continuous learning. The focus is speed and adaptability.

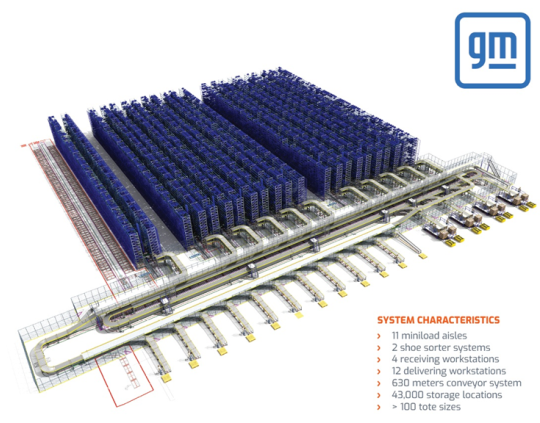

Figure 3. 3D project image for General Motors of Anji.

Reporter: How does the joint venture influence Inther’s global innovation pipeline?

Hermsen: It’s become a second R&D ecosystem. Our European and Chinese teams share core design libraries but adapt hardware for different warehouse profiles. Whether a conveyor is built in Venray or Suzhou, it integrates seamlessly through our Inther LC software — that’s the power of a hybrid system architecture.

Reporter: Many companies worry about losing consistency when they localize production. How do you avoid that?

Herder: By making standards sacred. Every component, sensor, and PLC template is validated through the same global test protocols. Our JV products must “feel” identical to European modules from a software and service perspective. That consistency is what makes us credible as a systems integrator.

Reporter: How do logistics needs in China differ from Europe?

Herder: China’s market evolves at lightning speed. Customers expect scalability, flexibility, and ROI in months, not years. That mindset shapes everything — modularity, plug-and-play designs, and the ability to expand automation step by step. It’s a perfect match for our philosophy of incremental, data-driven improvement.

Reporter: What are some tangible advantages of producing locally?

Hermsen: Faster project execution and fewer dependencies. The JV can pre-kit conveyor modules and deliver directly to sites. There’s no ocean freight, no customs delay — just readiness. That’s vital when a retailer wants a system running before Singles’ Day, Lunar New Year or Black Friday (esp. for e-commerce companies with global online customers).

Reporter: How do you handle intellectual property and quality control in such a setup?

Hermsen: We separate ownership from operation. Core IP — our controls, interfaces, and design rules — stays with Inther. The joint venture focuses on manufacturing excellence and market adaptation under those frameworks. Quality control runs through our shared ERP and testing systems, ensuring identical performance metrics worldwide.

Figure 4. Inther Group headquarters in Venray, The Netherlands.

Reporter: Does the Chinese operation influence projects outside China?

Herder: Absolutely. Dual sourcing means more resilient supply chains for global customers. It also opens faster scaling options in Asia-Pacific — no import duties, shorter lead times, and better after-sales support. It’s a competitive advantage that benefits all our clients.

Reporter: Will the JV expand into other types of equipment beyond conveyors?

Herder: Possibly, but we’ll stay focused. We’re targeting standardized, high-throughput components — the building blocks of reliable automation. Anything that improves time-to-value and uptime, without overcomplicating maintenance, is within scope.

Closing Thoughts

Reporter: Finally, how do you measure success for your China strategy?

Hermsen: Three things: lead-time reduction, consistent system performance, and local innovation feeding back into our global solutions. If we can deliver faster, maintain quality, and push the envelope of what’s possible — then China isn’t just another region for us. It’s the engine room of continuous improvement.

Herder (closing): We didn’t go to China just to sell; we went to evolve. The logistics revolution is happening here in real time.

Both: If you want to shape the future of material handling, you have to be where it’s being reinvented every day — and that’s China.