A-FRAME

Quick processing of complex orders

A-Frame key features

products

ejectors

stacks/ejector

windows/hour

Inther A-Frame

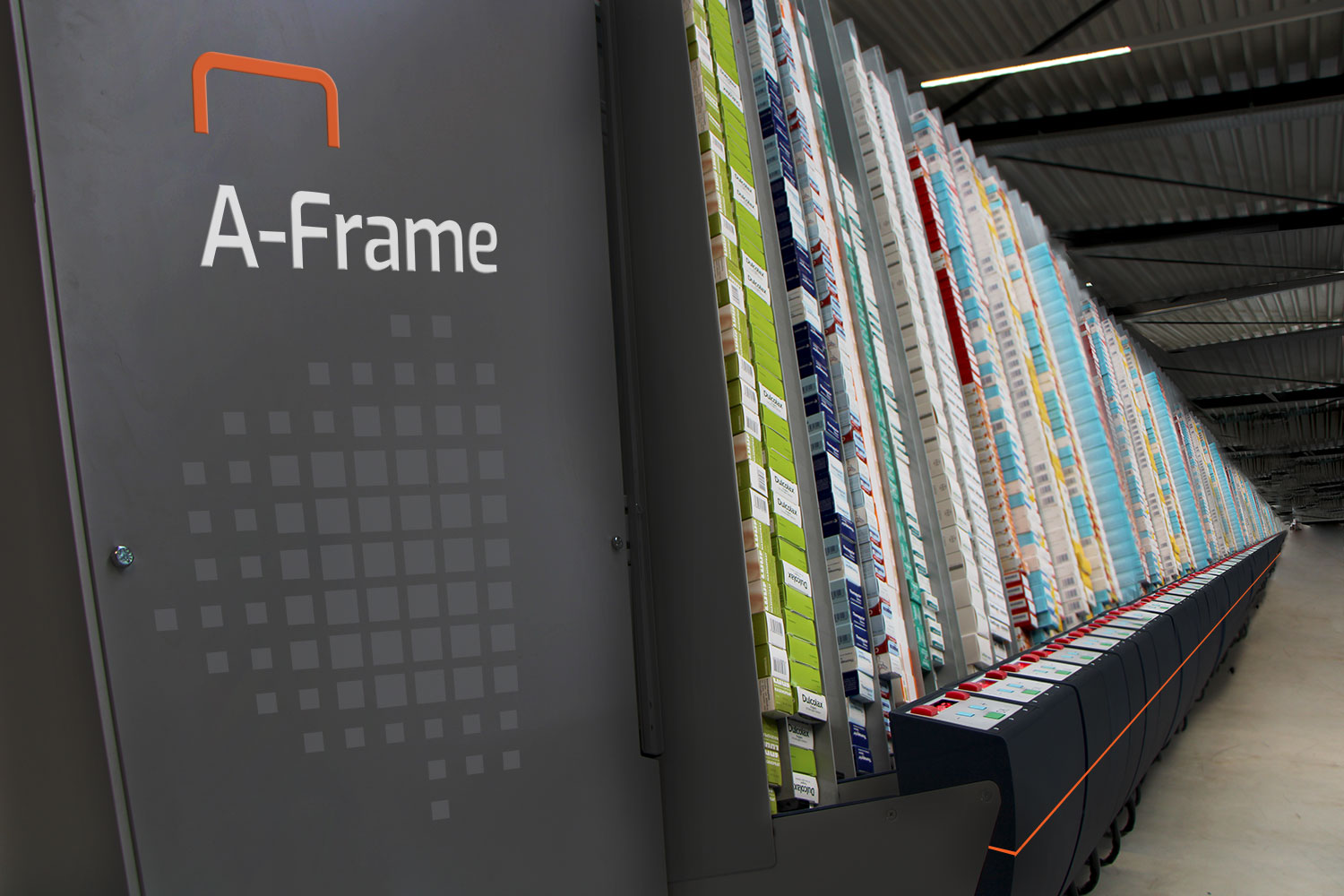

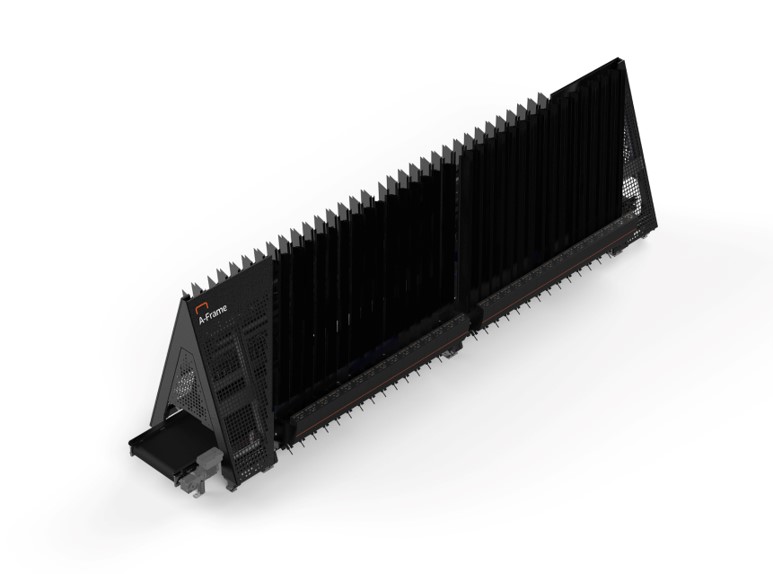

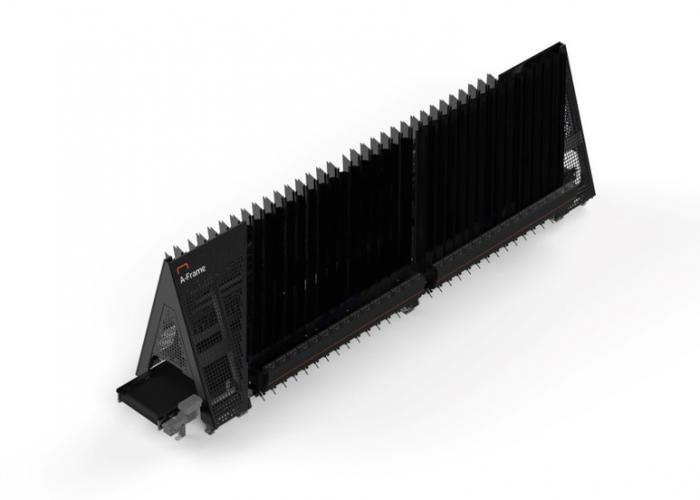

The A-Frame is a fully automatic solution for quickly processing complex orders, guaranteeing the highest possible productivity and an optimal material flow, even at peak loads. This proven technology is especially used in pharmaceutical distribution, but also ideal for other industries with high volume orders consisting of small, fast moving items in similar cuboid packaging, like cosmetics, tobacco and small office supplies. The A-Frame from Inther is distinctive by its high level of flexibility. The product channels are adjustable so that two columns of smaller packages can fit in one dispenser. Intelligent ejectors ensure a fully automatic, safe and error free processing of products. A sensor also calculates the height and thus the number of articles in the column, with the addition of a measured ‘indentation percentage’. This is an additional quality check that monitors the status of the items and ensures that warehouse staff are properly and optimally replenishing the A-Frame when needed. Therefore, the number of processing errors remains low and the output increases.

Advantages

-

Fully automatic and quick processing of complex orders

-

Integrated and unique check and video footage assure maximum control

-

Modular design for quick and low-cost extension of capacity

-

LOT/Batch tracking possible inside a product channel

- Adjustable ejector channels allow for large variety sized products to fit

Fast and flexible

The A-Frame from Inther Group provides an excellent solution to challenges of warehouses, that have to deal with peak times and various demands from different market channels. It collects up to five products per second per ejector, moves articles up to 1 meter per second, contains height verification, and offers the user up-to-date file management. With this solution, high quality order processing is consistently delivered and the warehouse moves smoothly and efficiently. With the A-Frame, Inther offers flexible and modular equipment, smart software and a compact design. The product channels are adjustable and intelligent injectors ensure a fully automatic, safe and maximum processing of products.

Unique features

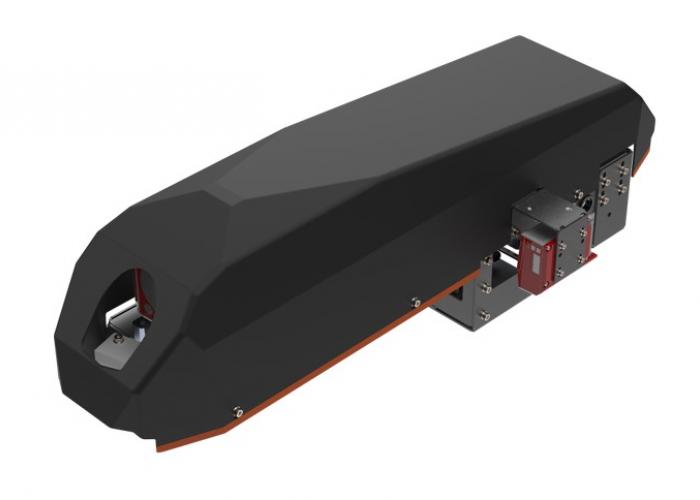

- Positioning Unit Measurement Apparatus (PUMA): measurement unit on top of the A-Frame automatically checks the stock level/additions for batch management

- Video registration: video images at the end of the A-Frame check administrative orders easily with the physical orders

- Heat mapping: this item use visualization in the A-Frame enables efficient distribution/spread SKUs over the A-Frame

- Modularity: simplifies and minimizes installation time and costs of extensions to the A-Frame

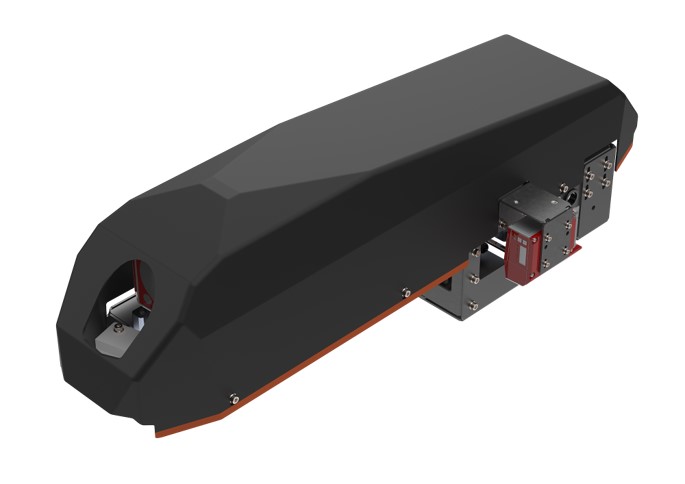

PUMA

The PUMA (Positioning Unit Measurement Apparatus) is a unique, optional measurement unit on top of the A-Frame that automatically checks the stock level/additions for optimally efficient stock and batch management. It calculates the height and thus the number of products in the channel, including the settlement of a measured 'indentation percentage'. This exclusive additional quality check monitors the stock status of products to reduce the number of refilling errors and downtime of your system.

Videos

relevant Downloads

Quick processing of complex orders