Inther Conveyor equipment

modular platform

Inther Conveyor equipment

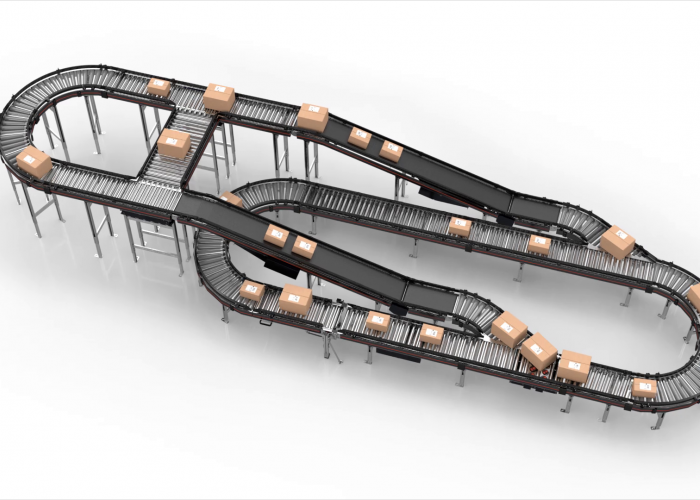

The modular platform of Inther Conveyor Equipment (ICE) is unique due to the short on-site installation and commissioning time. Our conveyors have been specially developed through the eyes of an integrator, which brings lots of benefits! All components (both mechanical and electrical) come pre-installed in our modules, including cabling and the correct E-plan codes.

The smart and flexible modules are available in various widths and are suitable for transporting all common goods in intralogistics. Inther Group provides you with a functional conveyor system with professional and thought through advice, rather than being a simple 'module seller'. And please be aware, that all our conveyor systems are made in the Netherlands!

Fully modular

Cabling & sensors integrated

Reduced on-site installation time

Plug & play

Made in the Netherlands

All conveyor products

With the CPS01 Carton Pull Sorter it’s possible to send out packages to sort. The package is pulled out by the driven roller which is covered with rubber for extra grip. The use of the outbound module means heavy mechanics are no longer needed. The Carton Pull Sorter is completely modular, which makes it easy to expand the number of chutes in the future.

With the CPS01 Carton Pull Sorter it’s possible to send out packages to sort. The package is pulled out by the driven roller which is covered with rubber for extra grip. The use of the outbound module means heavy mechanics are no longer needed. The Carton Pull Sorter is completely modular, which makes it easy to expand the number of chutes in the future.

The CT01 Roller Conveyor Alignment 24V aligns materials to the left or right, for example to obtain an ideal scanning moment or to apply a label to the material.

The CT01 Roller Conveyor Alignment 24V aligns materials to the left or right, for example to obtain an ideal scanning moment or to apply a label to the material.

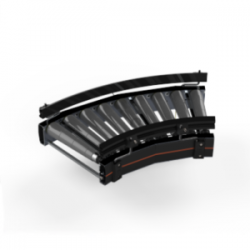

The CT01 Roller Conveyor Curve 24V transports materials automatically using a programmed controller. Each zone is driven by a motor roller that drives the non-driven rollers by means of belting. The bend can be up to 15 degrees each time it’s expanded. This is the only modular conveyor bend in the world!

The CT01 Roller Conveyor Curve 24V transports materials automatically using a programmed controller. Each zone is driven by a motor roller that drives the non-driven rollers by means of belting. The bend can be up to 15 degrees each time it’s expanded. This is the only modular conveyor bend in the world!

The CT01 Roller Conveyor Merge 24V combines materials from two transport lines by sending the materials onto the track when there is an empty space in the material flow. The Merge 24V can also be used as an output path by using a KP01 Pop-up Module to send materials left or right.

The CT01 Roller Conveyor Merge 24V combines materials from two transport lines by sending the materials onto the track when there is an empty space in the material flow. The Merge 24V can also be used as an output path by using a KP01 Pop-up Module to send materials left or right.

The CT01 Roller Conveyor Straight 24V transports materials automatically with the aid of a programmed controller. Each zone is driven by a motor roller that drives the non-driven rollers by means of belting.

The CT01 Roller Conveyor Straight 24V transports materials automatically with the aid of a programmed controller. Each zone is driven by a motor roller that drives the non-driven rollers by means of belting.

The CT01 Roller Conveyor Straight Accumulating 24V automatically transports materials using a programmed controller. Each zone is driven by a motor roller that drives the non-driven rollers by means of belting. The Straight Accumulating 24V neatly positions the boxes on the track with fixed gaps.

The CT01 Roller Conveyor Straight Accumulating 24V automatically transports materials using a programmed controller. Each zone is driven by a motor roller that drives the non-driven rollers by means of belting. The Straight Accumulating 24V neatly positions the boxes on the track with fixed gaps.

The CT01 Roller Conveyor Straight General 400V automatically transports materials. The conveyor is driven by one central drive that controls a belt that runs under the track against the rollers.

The CT01 Roller Conveyor Straight General 400V automatically transports materials. The conveyor is driven by one central drive that controls a belt that runs under the track against the rollers.

The gravitational conveyor transports materials by hand or by gravity through an angle of inclination. This conveyor is often used for workplaces where the materials are manually picked or set up.

The gravitational conveyor transports materials by hand or by gravity through an angle of inclination. This conveyor is often used for workplaces where the materials are manually picked or set up.

The CT02 Belt Conveyor Decline 400V transports materials using a driven conveyor belt. With this module it is possible for materials to descend from and/or to another floor.

The CT02 Belt Conveyor Decline 400V transports materials using a driven conveyor belt. With this module it is possible for materials to descend from and/or to another floor.

The CT02 Belt Conveyor Incline 400V transports materials using a driven conveyor belt. With this module it is possible to rise from and/or to another floor.

The CT02 Belt Conveyor Incline 400V transports materials using a driven conveyor belt. With this module it is possible to rise from and/or to another floor.

The KP01 Pop-up Module 24V is used to transfer materials to the left or right to another conveyor at an angle of 30 degrees.

The KP01 Pop-up Module 24V is used to transfer materials to the left or right to another conveyor at an angle of 30 degrees.

The KP02 Transfer Module 24V is used to channel materials in or out of another conveyor using belt cassettes. This is done at an angle of 90 degrees.

The KP02 Transfer Module 24V is used to channel materials in or out of another conveyor using belt cassettes. This is done at an angle of 90 degrees.

The KP04 Liftup Gate can be raised at an angle of 90 degrees with a lifting movement. This gate provides access to the other side of the conveyor if something is needed or in order to reach an exit. The 24V Liftup Gate can be opened independently with the support of the gas springs which minimize the weight to be lifted.

The KP04 Liftup Gate can be raised at an angle of 90 degrees with a lifting movement. This gate provides access to the other side of the conveyor if something is needed or in order to reach an exit. The 24V Liftup Gate can be opened independently with the support of the gas springs which minimize the weight to be lifted.

Contact form