19 February 2026

How do you transform an outdated distribution center into a fully automated operation without shutting down the ongoing operations for a single day? For Zeeman, this wasn't a theoretical challenge, but a realistic starting point. Inther Group took on the challenge and, together with Zeeman in Alphen aan den Rijn, wrote a logistics story centered on technology, collaboration, and courage. A journey filled with technological innovations, logistical puzzles, and organizational challenges—but above all: a shared belief in the concept.

The reason: end-of-life and a look to the future

In 2018, Zeeman embarked on an ambitious project to modernize its existing logistics operation. The retailer, known for its extensive store network across Europe, wanted to move away from its outdated, manual sorting system and transition to a future-proof, automated concept that could seamlessly grow with the organization's retail ambitions. Together with Inther, a comprehensive solution was developed that prioritized efficiency, ergonomics, and scalability.

A key focus was improving the fill rate of roll containers and truck loading, increasing SKU flexibility, and enabling just-in-time delivery to its current more than 1,400 stores in Europe. Furthermore, improving ergonomics and sustainability in the warehouse was a goal. Adding to the complexity was the fact that all of this took place in a brownfield site: the existing building in Alphen aan den Rijn remained operational throughout the entire renovation.

Zeeman opted for a complete system transformation. They wanted to not only renew their logistics operation but also completely overhaul it: new processes, a new system design, new technologies, and collaboration with multiple integration partners. "It's a complete redesign of all processes, systems, and working methods. Moving from a 25-year-old, ingrained sorting operation to a state-of-the-art shuttle system, all within the same building, has challenged us immensely," explains Bas Hoekstra, Director of Supply Chain at Zeeman.

As lead integrator, Inther was tasked with bringing all of this together and was therefore responsible not only for the design, system selection, integration, and implementation of the chosen solution, but also, and more importantly, for connecting all the links in the chain. Martijn Herder, CEO of Inther Group: "We collaborated with Zeeman in the preliminary design phase, based on clear principles. Based on this, the entire system was designed and validated through simulations."

The Inther solution: a comprehensive modular concept supported by AI

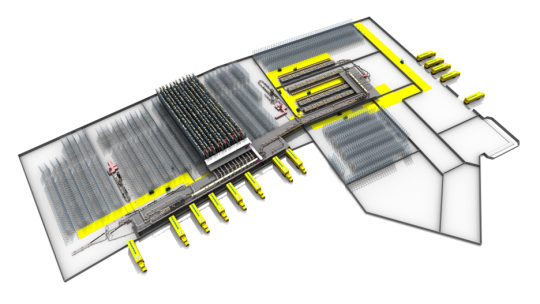

To realize these ambitions, a fully automated system concept was chosen, based on realistic data analysis and a modular approach. This innovative combination of existing technologies, applied in a way that perfectly suits Zeeman's high volumes and specific distribution challenges. The core of the system is a shuttle storage system with 6 AS/RS aisles, where each box is individually accessible. Thanks to different storage patterns, a wide variety of box sizes can be stored directly. This eliminates SKU limits and allows each order line to be precisely positioned for optimal container fulfillment. This provides maximum flexibility and enables order optimization at the box level for loading and shipping.

The system is fully integrated with both Inther ILC and external software. The result is a flexible shuttle system that enables Zeeman to efficiently manage all incoming and outgoing goods flows:

- Cross-dock flow: OEM boxes enter the system directly from the container

- Inventory items: Depalletized, buffered, and processed via the shuttle

- Order-picked goods: Picked via Pick-to-Light and then directly to the shuttle

All boxes—picked or not—pass through the shuttle system. This forms the central backbone of the operation. These boxes, regardless of their origin, are automatically stored in the shuttle and intelligently reshuffled to be processed and stacked in roll containers at the right time and in the right order, using the smart Inther ILC software and algorithm-supported loading. This is essential for optimal fill levels. After all, every cubic centimeter counts—literally.

All boxes—picked or not—pass through the shuttle system. This forms the central backbone of the operation. These boxes, regardless of their origin, are automatically stored in the shuttle and intelligently reshuffled to be processed and stacked in roll containers at the right time and in the right order, using the smart Inther ILC software and algorithm-supported loading. This is essential for optimal fill levels. After all, every cubic centimeter counts—literally.

Service and collaboration as the foundation for continuous optimization

Inther Group not only supervised the design, realization, and implementation of the system but also played a leading role in the service and maintenance process. From the outset, the specialists from Inther's service department were involved and worked closely with Zeeman's technical department. Maintenance plans were developed together, spare parts were tested, and SLAs were aligned with the operational reality.

The system is now running stably, and further refinements are being worked on daily based on real-time data. The positive collaboration with Zeeman is also reflected in joint improvement projects that benefit both Zeeman and Inther, such as data science dashboarding, predictive maintenance, and fill rate optimization.

Result: a scalable, future-proof system for 1,400 stores

The project spanned several years, with phases of analysis, design validation, implementation, and optimization. After completion, Zeeman will have a fully scalable system, independent of item structures, and capable of operating without SKU limits. Tens of thousands of boxes are processed daily to supply more than 1,400 stores. The entire operation—from receiving to shipping—is focused on flexibility, speed, and fill level optimization—and is future-proof.

Herder: “Although the combination of technologies is new, the concept builds on Inther's experience from previous projects. What makes Zeeman unique is the scale and the way everything is integrated. The combination of automated storage, advanced picking methods, smart sorting, and the use of AI for depalletizing is rarely seen in the retail sector in this way.” André Peppelman, Supply Chain Development Manager at Zeeman, adds: “With so many different suppliers, Inther has performed its integration role well, a reliable partner that brings the components together into a single, functioning whole.”

Results at a glance

- No more SKU limits: each box can be individually controlled

- Optimal container loading through sequence-based supply

- Flexibility in flow management: direct cross-docking, inventory, or order picking

- Integrated AI and pattern recognition for depalletizing

- Reduced physical strain and improved ergonomics

Technical system features

| Component | Specification |

| AS/RS Shuttle | 6 aisles |

| Storage capacity | 60,000 – 100,000 boxes |

| Sorters | 2 shoe sorters |

| Channelizers | 2 units |

| Pick-to-Light workstations | 20 |

| Pick-to-Light locations | 960 |

| Automatic loading | 6 Elten stacking stations |

| Load carrier type | Rolling containers |

Project details summarized

- Client: Zeeman

- Sector: Non-food retail (clothing, accessories)

- Location: Alphen aan den Rijn (NL)

- Objectives: Increase loading rate, improve availability, optimize ergonomics

- Solution type: Fully integrated warehouse system

- Details: Implementation during continuous operations (no greenfield), limited dock capacity

- Technologies: Shuttle, (de)palletizers, pick-to-light, algorithm-supported loading, box erectors, roll container loading, visualization and control, Inther's own conveyor equipment, AMR, WMS integration

- Goods flows: OEM cross-dock, inventory, picking

- Partners: Manhattan, DGS, TGW, CICT, Elten, Lantech.