Blokker

Distribution centre - Geldermalsen, The Netherlands

Facts and figures

m2 Surface area

SKU's

Pallets in bulk stock

Pick-to-Light carts

Blokker

“Logistics is no longer an obstacle to the implementation of the commercial strategy. Our distribution center has become a sales machine.” – Roel Megens, DC manager at Blokker

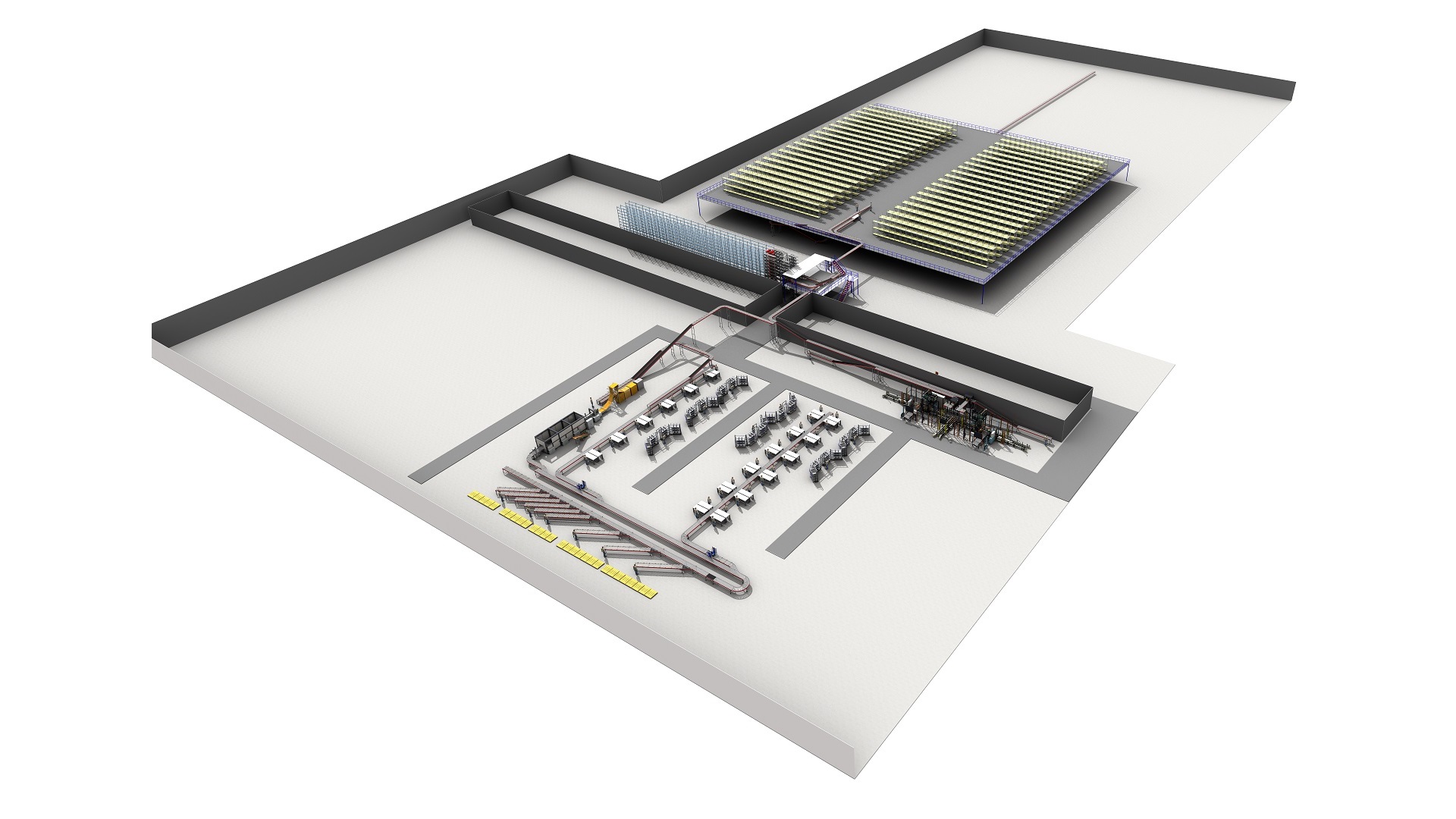

Store chain Blokker has drastically reduced its logistics costs by integrating its operations for e-commerce and brick and mortar logistics. A sophisticated order picking concept has been designed in the thirty-year-old distribution center in Geldermalsen. Dc manager Roel Megens: “Our logistics can now grow into the driver of the commercial strategy.”

Today, many retailers are struggling with the integration of e-commerce and store logistics. The question being asked: how should you combine both operations in one DC? "Most retailers emphasize the differences between the two operations. Then it is indeed difficult to integrate it. However, we have looked at the similarities, which prove to be larger than is often thought", says Megens. The focus on the similarities between the two operations has led to a logistics concept that no longer distinguishes between picking e-commerce orders and store orders. Both order flows are handled simultaneously in a completely refurbished area. "Only after order picking do we make a split in internet and store flows", says Megens.

Shuttle system as a buffer

The shuttle system is key in this area. Here, all full bins supplied by the conveyor are temporarily stored. They remain in the shuttle system until the relevant orders are complete. The shuttles then ensure that the bins for each store are unloaded at the right time in the right order. They then go to an automatic tray stacker, where they are placed in stacks of eight on a dolly. That dolly is then positioned with the roll containers in the correct preparation area on the shipping floor. The WMS stops all orders with one order line in a separate batch, so that the bins with these single-line orders are transported directly to a packaging machine. This machine packages the items automatically in a customized box.

Intelligent pick carts

The redesigned area of the DC consists of two different parts. The most complex part takes up the least space, but counts for the largest part of the range of products: the small items and the slow runners. In this area the articles with the highest turnover are on the ground floor in flow racks or on pallets. The articles with the lowest turnover are on the new mezzanine fl oor with shelf racks. Pallet racks stand against the walls around this area to supplement the picking stocks. "We call these the close-to-fi ll locations", says Megens. Order pickers make their rounds with intelligent pick carts that off er space for eight bins. The intelligence is visible through the pick-to-light displays on each cart. As soon as the order picker scans the barcode of the pick location, these displays indicate how many pieces must be placed in each bin.

Download the case study